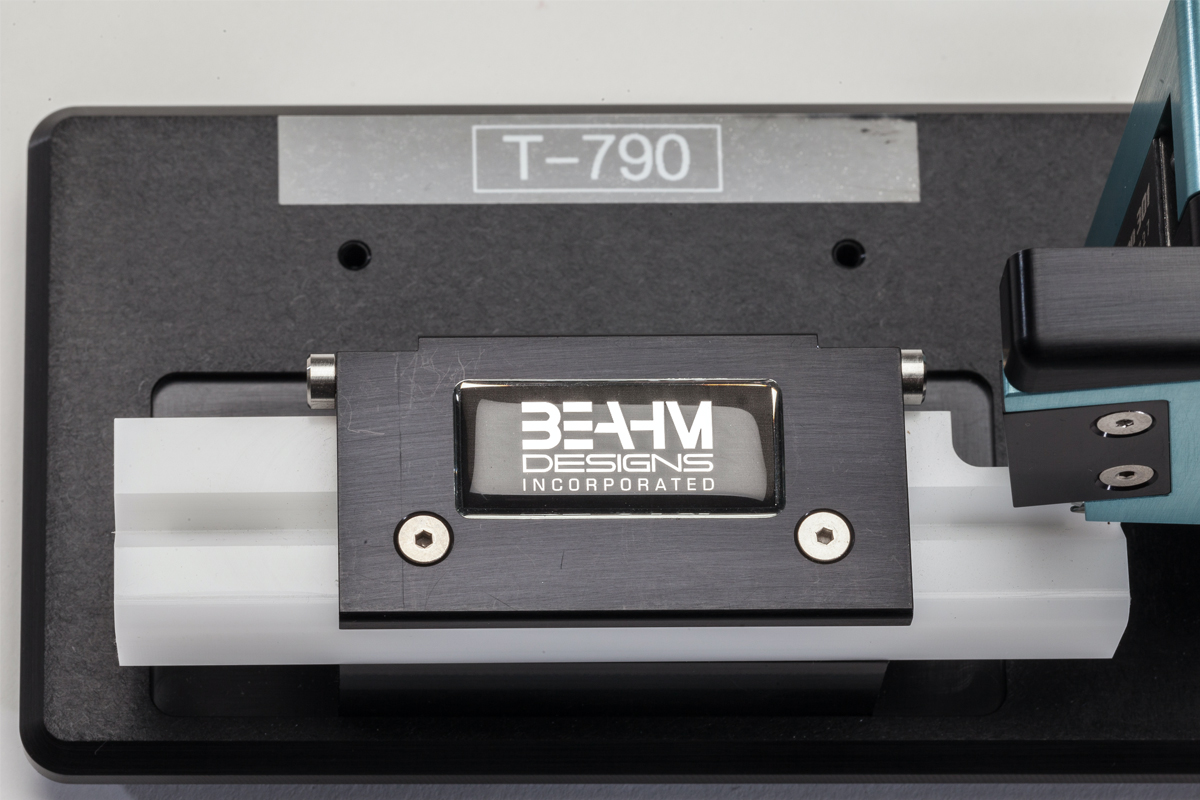

Heat Shrink Removal Tool – Platform Stripper

What is Heat Shrinking? Heat Shrinking is a common process used in medical device manufacturing to enable thermoplastic bonding. The materials being bonded have a lower melting point than the heat shrink which enables the shrink to compress the materials together when they are in a melted state. After the product is cooled the heat shrink layer needs to be removed. Heat Shrink Removal Tools are often used to peel and remove heat shrink from mandrels and tubing assemblies. Our heat shrink removal tool solutions are used to minimize operator processing time and increase overall performance of products. Process Overview:

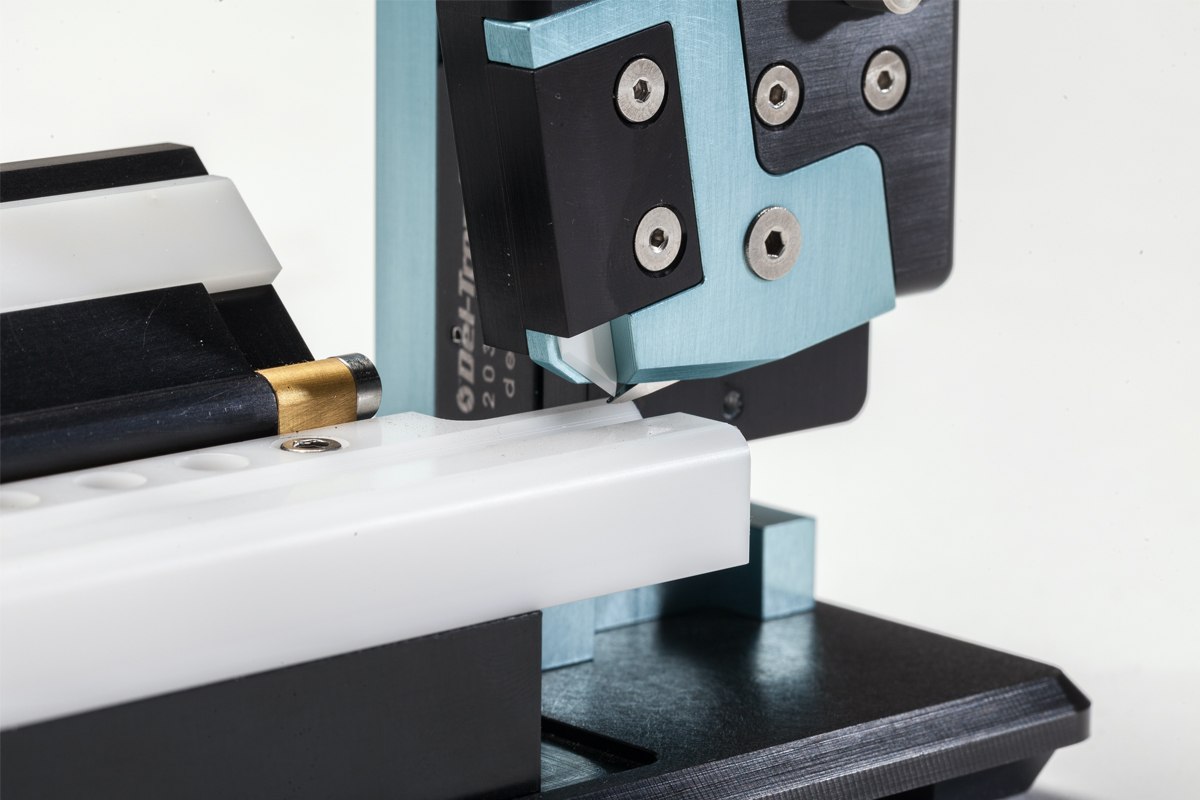

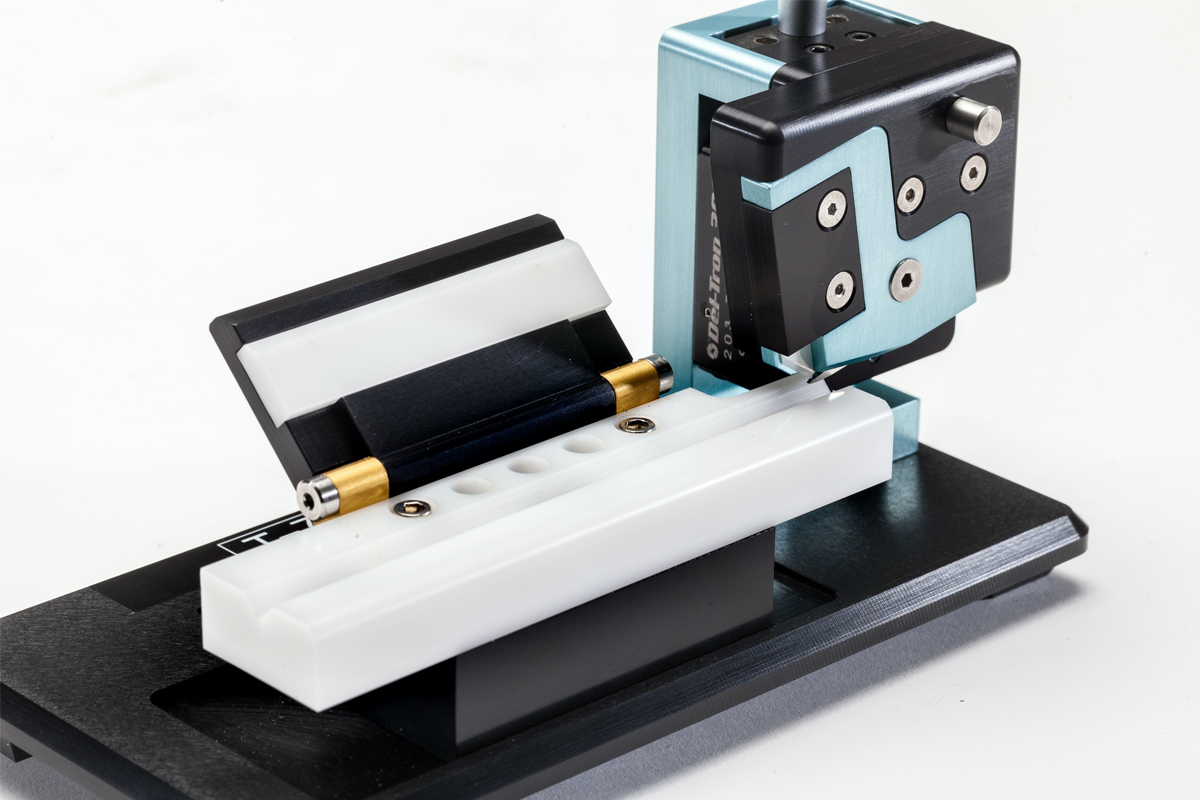

- A guide pin slides between the heat shrink layer and over the laminated product.

- As the shaft subassembly is advanced, the heat shrink layer is guided into the long-life blade, creating a longitudinal slit through the heat shrink, facilitating simple peel-away removal.

- This simple process only takes seconds to complete.

- Over 24,000 linear inches blade life.

Material Use & System Compatibility Our easy to use heat shrink removal tools are highly configurable for the fast removal of any length of heat shrink along a shaft. These tools remove heat shrink from medical devices during manufacturing. The Platform Heat Shrink Removal Tool is a fast and easy to use platform that protects your product during the heat shrink removal process. This system can be configured to meet any specification surrounding heat shrink wall thickness, diameter and a variety of heat shrink materials. Our heat shrink removing tools are fully adjustable and Feature adjustable guide/blade height to accommodate diameters from 0.060” to 0.25” standard. Maximize Productivity & Production Yields Save time and money with a heat shrinking tool that lasts. Unlike stainless razor blades, the specialized composite blades blade stays sharp and does not oxidize after a few uses. There is over 24,000 linear inches in blade life. The Platform Heat Shrink Removal Tool is heavily relied on and used globally as a leading industry shrink removing solution. It helps increase production and increase production yields by limiting skive damaging and reducing overall damaged parts in your production line. Other Heat Shrink Removal Tools: Hand Held Heat Shrink Remover – For Short lengths such as bonding sleeves This heat shrink removing tool works with all thermoplastic materials. The heat shrink tubing is assembled over the materials to be reflowed. The most common Heat shrink is FEP however, polyolefin and polyester are also viable options. Mandrels range from the standard PTFE coated stainless steel or hypo tubes to silver plated copper and is application driven. Vee-Base Heat Shrink Remover – For Medium Lengths The typical lamination temperatures range from 425 deg f – 650 deg f. Heat delivery is accomplished via a range of multi-port or full circular thermal nozzles and selection is dependent on material diameter. The nozzle traverse speed depends on several variables including total wall thickness of all materials braid density, core mandrel diameter. Some applications require tension in order to further reduce material diameter and this can be accomplished using either a pneumatic tensioning mechanism or hanging weights.

For Service and Support

Call (928) 556-3109 or Email service@machinesolutionshost.com