High Speed Vertical Catheter Laminating Machine

(VL400/ VL1000)

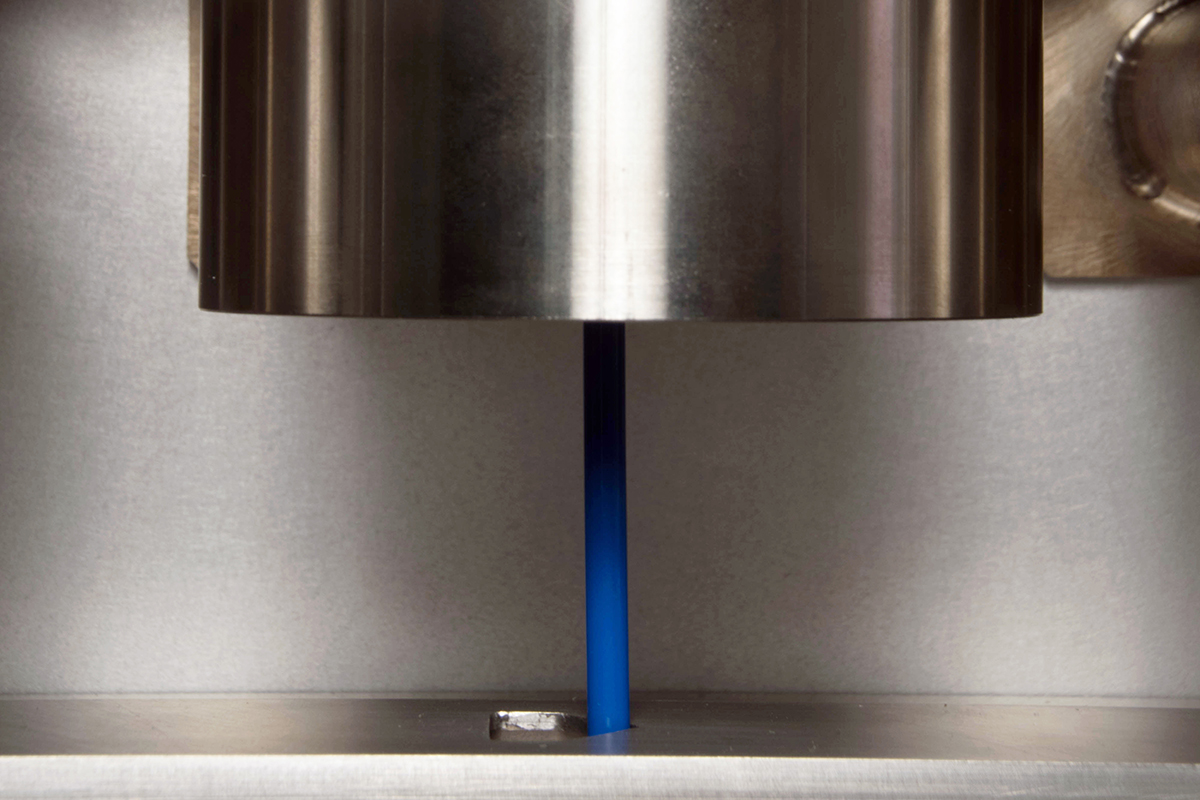

The MSI Catheter Reflow Vertical Laminator is the most efficient method to reflow plastic over a braided catheter sub-assembly and liner. Our newest model has been re-engineered to make loading of the product easier for operators and features a redesigned nozzle which can run 2.5 times faster than previous models.

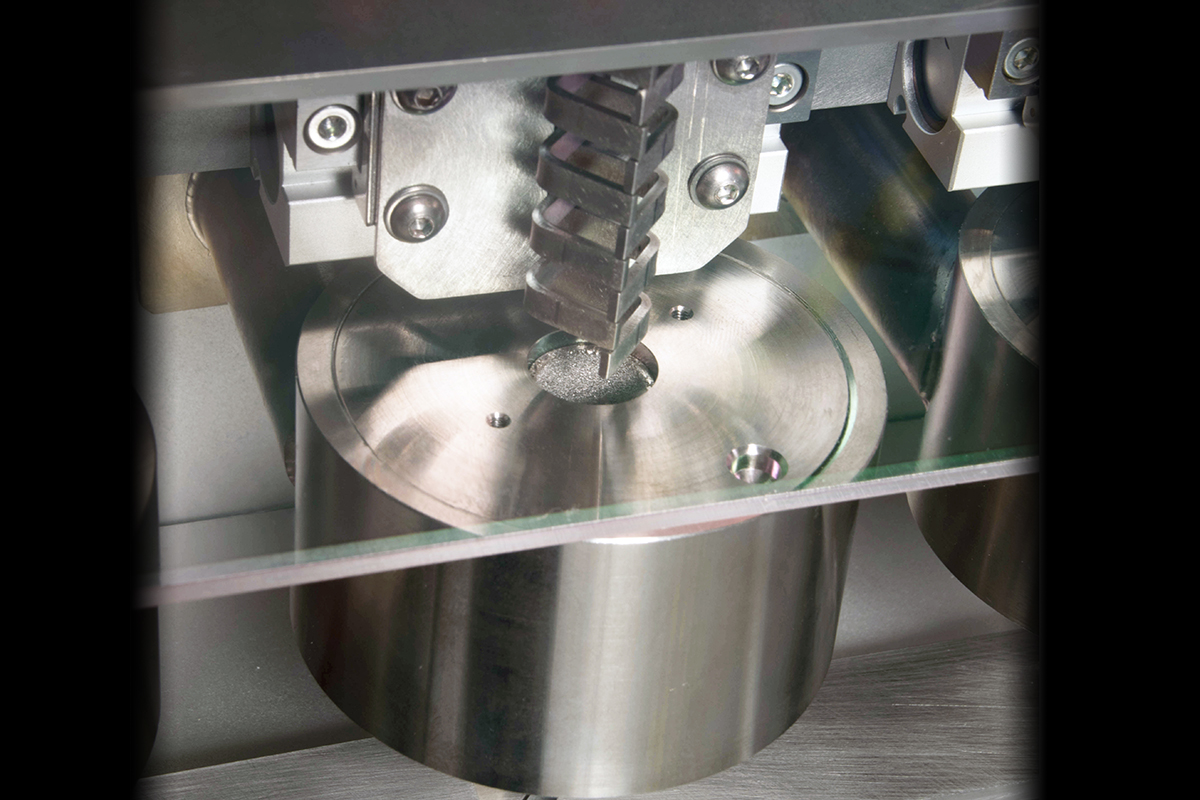

The VL is available in 4 or 10 Lane configurations to meet your production volume needs. This machine is an ideal complement to the SteegerUSA braiding and coiling machines as it is designed to uniformly laminate multi durometer tubing to create a braided catheter with high yields and repeatable results.

We have re-engineered our High Efficiency Microswirl 360° thermal nozzle to ensure superior uniform heating characteristics and minimizing the incidence of hot or cold spots during the shrinking process. Digital flow controls and improved flow control monitoring components ensure that all 10 nozzles output repeatable product. Our initial testing showed the new nozzles were capable of running product up to 2.5 times faster than previous models.

The new Universal grippers and product funnels accommodate a wide range of product sizes from 0-34Fr eliminating the need to switch grippers. The loading rack can be programmed to lower to a comfortable loading height so that operators can load product quickly and comfortably.

The touchscreen PC operator interface is designed for saving and retrieving numerous programmable parameter profiles. The machine is capable of 6 length and speed transitions within a single cycle and features tubing guides to ensure product centering within the heat zone and independent temperature control of each thermal nozzle.

Product Features:

- Minimizes incidents of hot spots, bubbles and delamination

- Uniform air flow and temperature around the entire circumference of your product

- Adjustable height gripper rack for ergonomic product loading

- 0-34Fr product grippers and optional centering guides

- 175, 205 or 255cm travel length options

- Profiles can be saved and recalled as needed, easy set up and providing a repeatable process.

- Optional system for constant tension of heat shrink

VERTICAL LAMINATION TEMPERATURE STABILITY & REPEATABILITY TEST DATA IS AVAILABLE HERE

Review Temperature stability Data

For Service and Support

Call (928) 556-3109 or Email service@machinesolutionshost.com