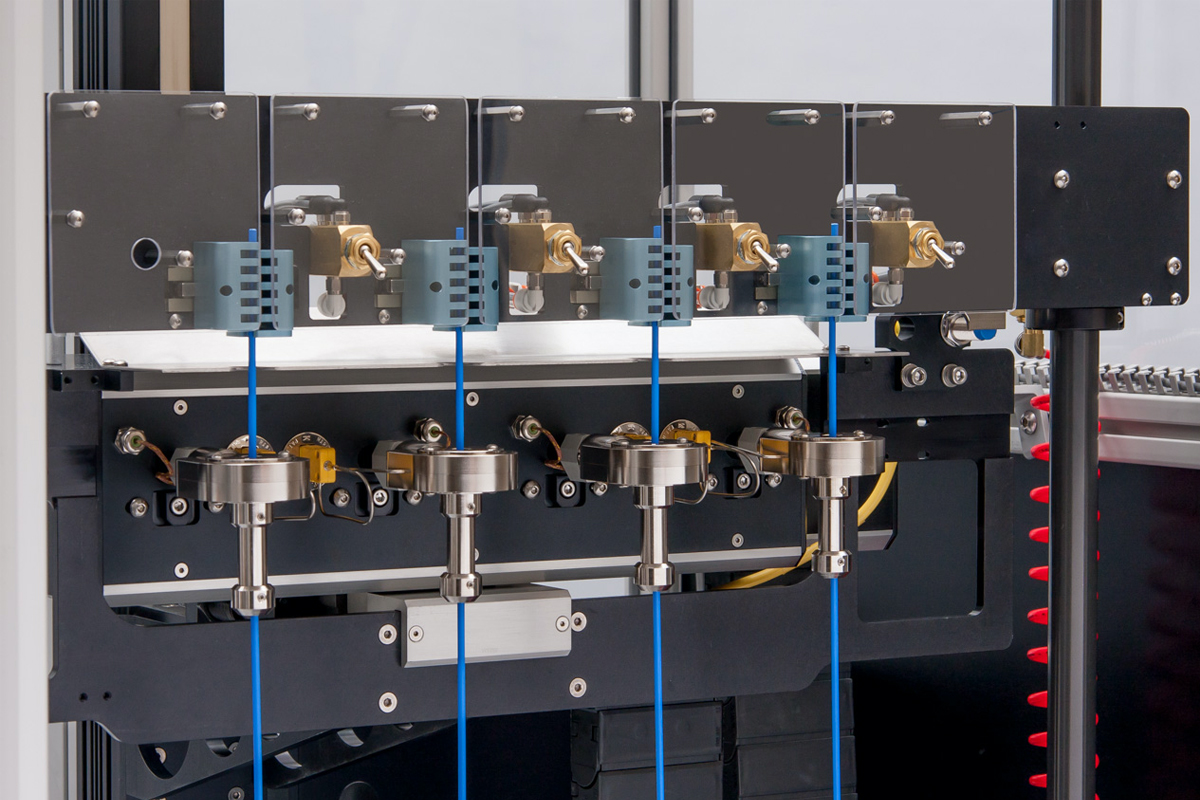

4-up Catheter Laminating Machine (810A)

Achieve repeatability and uniformity with our Vertical Laminator (810A). Offering an array of thermal nozzle options (including Vortex 360 deg), this system delivers strictly controlled heated air while traversing process appropriate thermal nozzles at a precisely regulated speed.

Process repeatability, high yield and uniformity are further reinforced with the use of tubing centering guides to ensure accurate catheter centering within the heat zone.

Traverse speed and length settings are entered via touch-screen HMI and a motion controller ensures precision and repeatability. This system is capable of multiple length and speed transitions within a single cycle and within the heat zone, and independent temperature control of each thermal nozzle.

Designed to Meet Manufacturing Needs:

- Tooling: Features process appropriate thermal nozzles (including Vortex 360 deg.)

- Temperature Range: Ambient- 750F

- Proven: Provides unsurpassed repeatable, uniform results.

- Capable: Multiple length and speed transitions within a single cycle.

- Thru Put: 4 component processing (6-Up also available upon request)

- Accuracy: High accuracy and repeatability of traverse speed and length

- Control: Independent temperature control of each thermal nozzle.

- Versatility: Up to 5 programmable rate and distance settings.

- Traverse Length: 175cm. Custom lengths available.

- Functional: Parameter configurations (recipes) can be named and saved

For Service and Support

Call (928) 556-3109 or Email service@machinesolutionshost.com