Your shopping cart is empty.

Horizontal Laminator

(Model 710A)

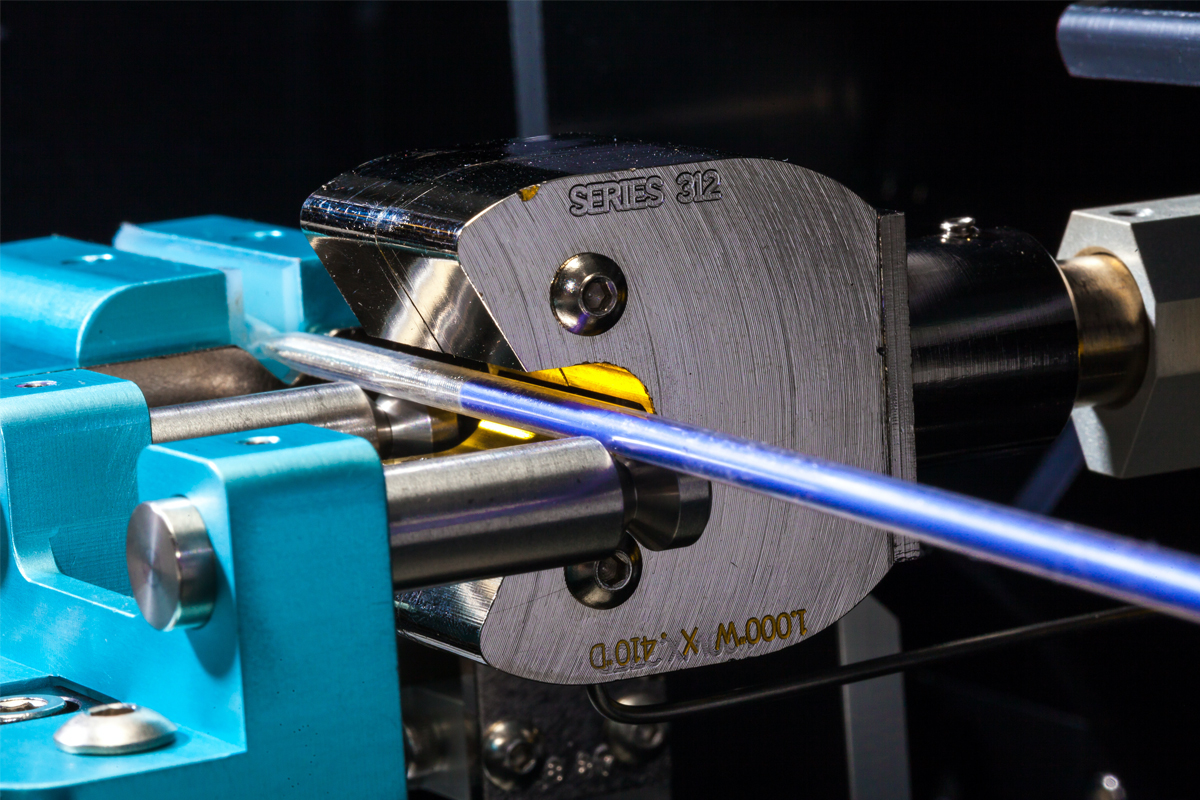

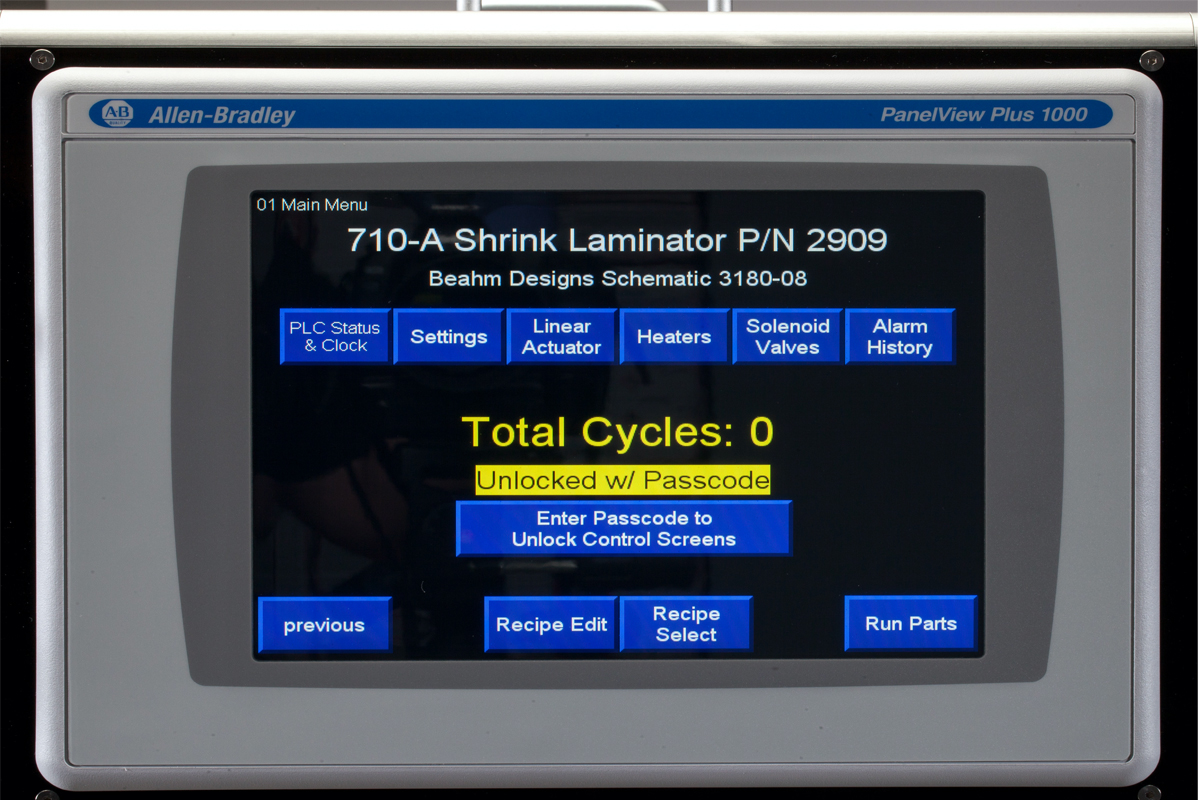

The Beahm Designs Inc. Thermal Traverse Laminator (710A), channels precisely controlled hot air to shrink, laminate or reflow thermoplastic materials into a single composite. This machine traverses a multi-port thermal nozzle along a specified length and speed to create optimal catheter lamination results. The touch screen HMI parameter interface provides recipe management and maintenance/parameter access password lock-out. A wide range of configurations and options are available.

This system gives you:

- Consistent laminations

- Process Control (ie temperature, traverse rate, expand pressure)

- Touchscreen HMI with storage for up to 100 recipes

- Full EH&S Safety Enclosure

- Pneumatic Soft Jaws (silicone)

- Vee-Guide Centering of Product within Thermal Nozzle

- Programmable Speed and Distance

- CE Compliant

Materials:

| Catheter Tubing Materials | Virtually all thermoplastics such as but not limited to; – Pebax – Nylon – Polyethelene – Polypropylene – Polyurethane – FEP – PTFE |

Features: |

|

| Tooling Options | Thermal Nozzle Grip tooling |

| Temperature Range | 200 – 750F |

| Catheter Lamination Lengths | Standard traverse length 20″ Available standard configurations of 34″ and 58″ |

| Traverse Speed | Available Speed: 0.1 – 20 mm/sec |

| Tubing Size | 1 to 31 Fr 0.013 in. to 0.375 in. |

| Facilities Requirements | 120VAC or 220VAC 50/60 Hz. 500 watts max. |

| Services | Equipment Design and Development Process Development First Article Samples – Prototyping Tooling |

—

For Service and Support

Call (928) 556-3109 or Email service@machinesolutionshost.com

© 2024 Beahm Designs. All rights reserved. Maintained by: Icovy Marketing - Medical Device Digital Marketing