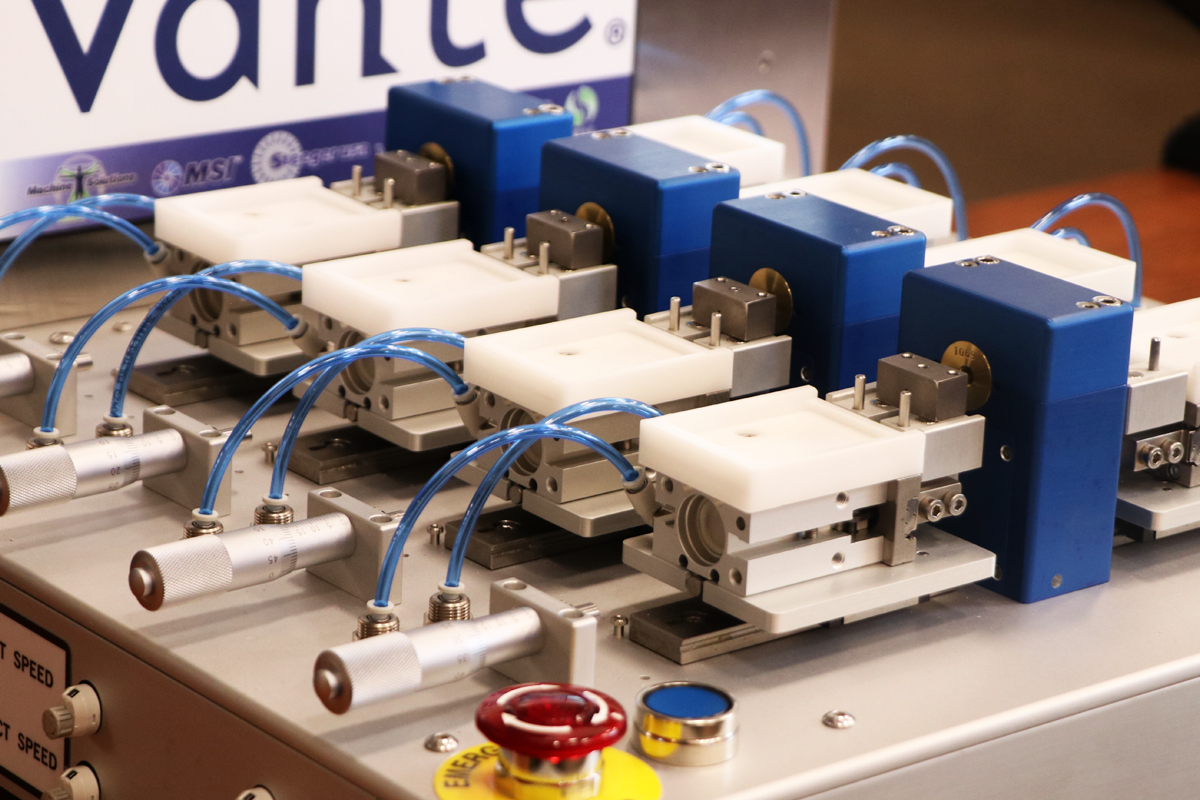

Vante Onyx

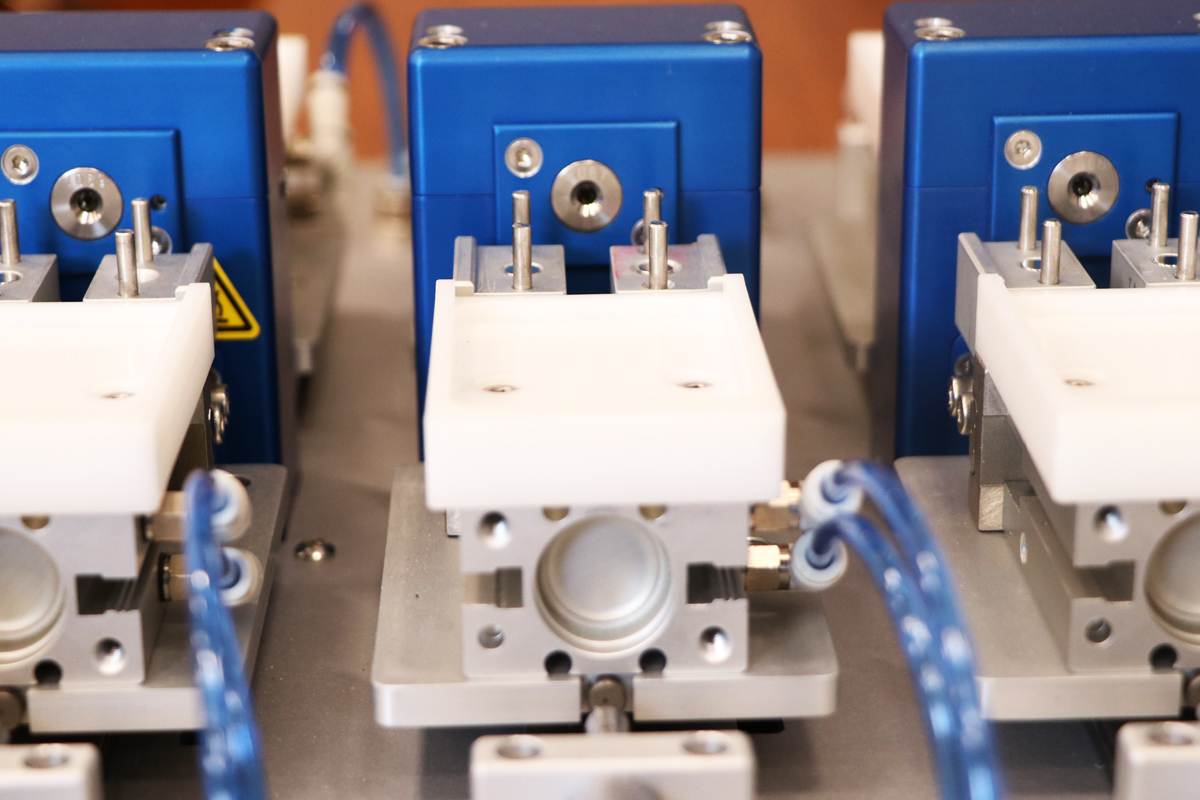

The Vante Onyx catheter manufacturing system is designed to maximize production output while minimizing operating expense in high volume production environments. This system incorporates production capabilities of up to four (4) independently controlled Vante tipping stations into a compact table top platform which can be supported by a single operator. The systems utilize a closed loop temperature control system which produces precision temperature control and heat placement for the fastest and most repeatable catheter manufacturing processes. It also features “Smart Mold” technology which provides the ability for parametric data to be stored in the mold module for auto configuration of the system. Process parameters are loaded quickly and reliably via system configuration sensing and software control. The mold assembly is designed for easy installation and removal from the platform. Each lane can run independent process settings to enable a variety of tipping, welding, and forming molds for many applications.

Numerous benefits include:

•Compact footprint which saves clean-room space

•Repeatable, high quality results

•Easy to set up and validate

•Quantifiable and validatable process

•High production first pass yields

• Quick and easy tooling change

Numerous features include:

•Digital Air Pressure Regulation

•Smart Mold

•Air cooled. No water chillers

•Closed loop temperature feedback

•Proprietary low mass mold design

•Operator safe so there are no hot spots or pinch points

•Grip-slip detector alarms if grippers reach the maximum extent of travel before completion of the tipping cycle.

•Precise heat placement

•Optical touch switch to initiate machine cycle

•Solid state circuitry

•Temperature repeatable to ± 1% up to 350°C and ± 2% for 350°C to 425°C

•Multi-level password protection

•Advance control system featuring alarm monitoring and data collection

For Service and Support

Call (928) 556-3109 or Email service@machinesolutionshost.com